Why Brass is Preferred Over Copper or Aluminum in Electrical Terminals

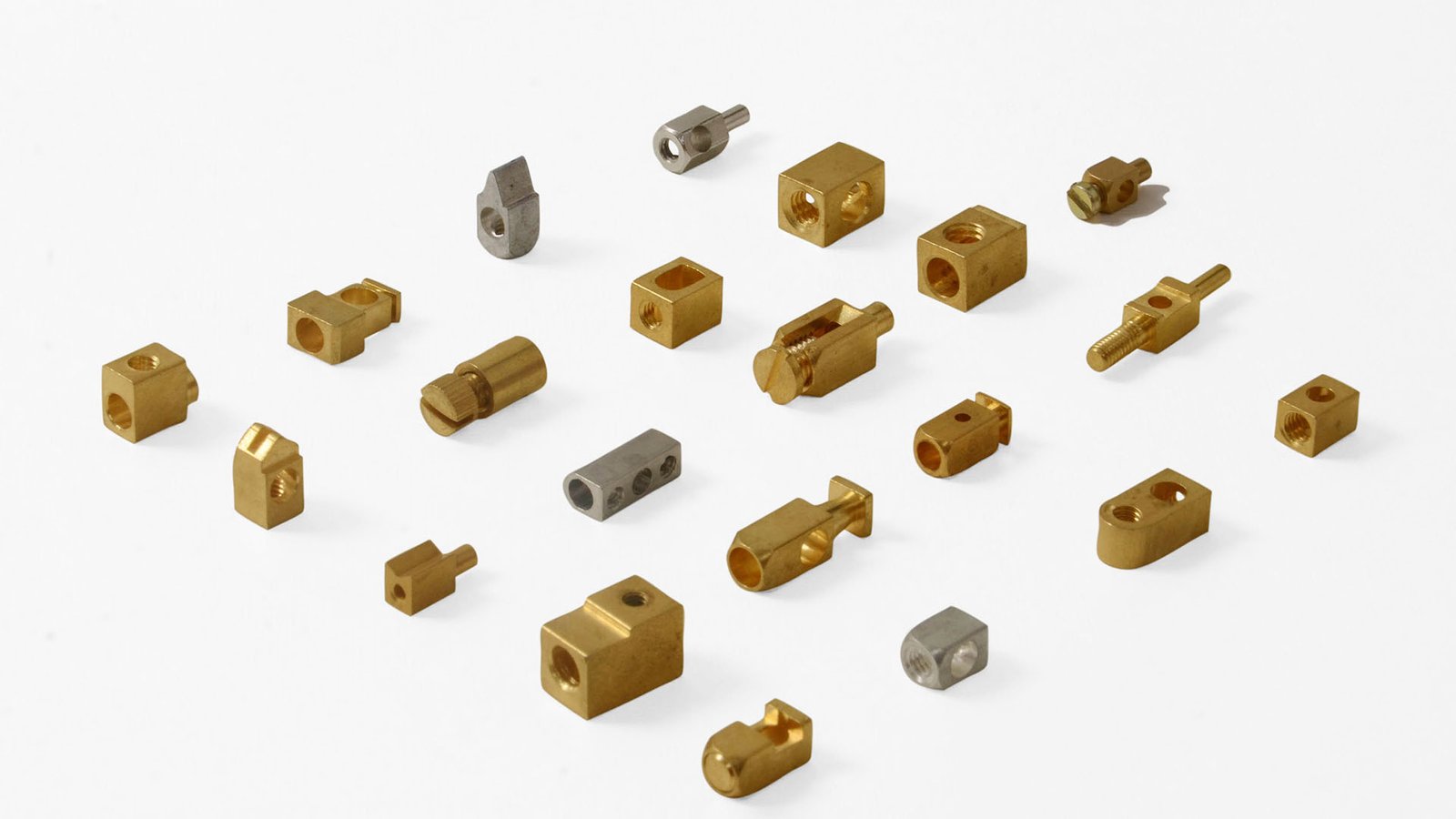

When it comes to electrical terminals, the choice of material significantly impacts performance, safety, and longevity. Brass is widely preferred over copper and aluminum in automotive, switchgear, control panels, and energy meters due to its unique combination of electrical, mechanical, and chemical properties.

1. Excellent Electrical Conductivity

Brass offers high conductivity, allowing for efficient current flow with minimal power loss. While copper has slightly higher conductivity, brass strikes a balance between conductivity and mechanical strength, making it ideal for terminals that must handle both electrical load and mechanical stress.

2. Superior Mechanical Strength

Unlike pure copper or aluminum, brass is stronger and more durable, reducing the risk of deformation or breakage during installation or under vibration. This makes brass particularly suitable for automotive connectors, switchgear terminals, and industrial panel boards.

3. Corrosion Resistance

Brass is naturally resistant to oxidation and corrosion, unlike aluminum which forms an insulating oxide layer, or copper which can corrode over time. This ensures long-term reliability and minimal maintenance in harsh environments.

4. Easy Machinability & Plating

Brass is easy to machine, crimp, and form into complex terminal shapes. It also accepts surface plating (tin, nickel, or silver) to enhance conductivity, corrosion resistance, and aesthetics, which is more difficult with aluminum.

5. Thermal Stability

Brass maintains its structural integrity over a wide temperature range, making it ideal for high-current or heat-prone applications in both electrical and automotive industries.

Conclusion

Choosing brass for electrical terminals provides a perfect balance of conductivity, strength, corrosion resistance, and durability. That’s why manufacturers and OEMs around the world consistently prefer brass over copper or aluminum for reliable, long-lasting electrical connections.

📖 Learn more about our precision brass terminals and connectors: Read Full Article